Depending on input, De L’or employs proprietary aqua regia, electrolytic and chlorination refining methodologies. As a full service precious metal premises, De L’or has significant capacity to refine the following metals:

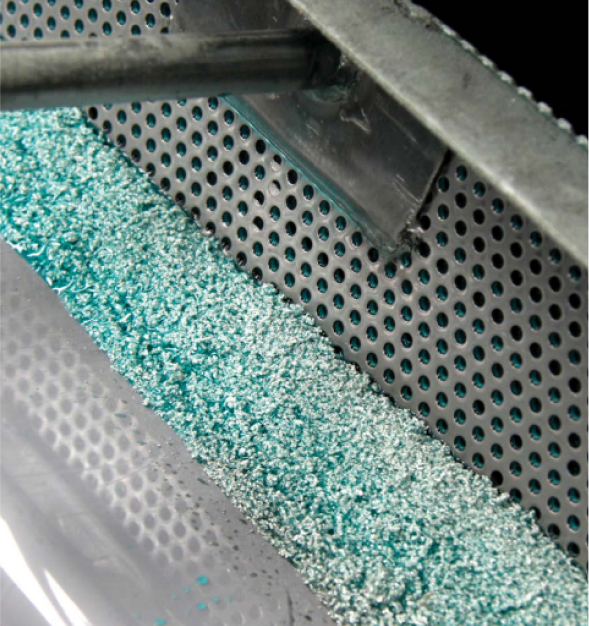

Upon receipt of the shipment at the refinery, De L’or inspects received packaging for damage as evidence of tampering. Before refining of received goods, De L’or conducts a controlled melting process that minimises melt loss to maximise return. The received material is then homogenised utilising the latest in international homogenisation methods.

De L’or manufactures an extensive range of finished and semi-finished products including cast bars, minted tablets and coins, minted blank tablets and coins as well as pure precious metal granules.

Certification and packaging guarantees purity, weight and assayed precious metal content of every product leaving the refinery.

At De L’or, the health and safety of our staff and the wider community in which we conduct business is of utmost priority. We are committed to maintaining international standards in health and safety, the environment, internal and external client relationships and risk management. De L’or has adopted the following policies to achieve this goal: